Discover Vin Hair’s inspects hair quality process, from sourcing to heat resistance checks, to ensure the product meets global export standards.

When it comes to human hair extensions, quality is everything-especially for overseas customers who expect consistency, durability, and a natural look. That’s why Vin Hair, one of Vietnam’s leading hair suppliers, is committed to delivering high-quality human hair extensions that meet high international standards.

So how does Vin Hair ensure each bundle is the best before export? Let’s examine their step-by-step inspects hair quality process that makes each order export-ready.

Contents

- 1. Introduction to Vin Hair

- 2. Step-by-step how Vin Hair inspects hair quality

- 2.1. Step 1: Hair collection & preliminary check

- 2.2. Step 2: Deep washing & sanitation

- 2.3. Step 3: Natural drying & texture preservation

- 2.4. Step 4: Sorting by length, texture & color

- 2.5. Step 5: Tangle & shedding resistance test

- 2.6. Step 6: Heat and dye resistance check

- 2.7. Step 7: Final visual and manual quality check

- 2.8. Step 8: Safe and branded packaging for export

1. Introduction to Vin Hair

Vin Hair Vendor is a well-established brand in Vietnam’s export market for human hair. With a reputation for offering 100% human hair directly from Vietnamese donors, Vin Hair has earned a reputation for quality, honesty, and customer satisfaction.

With clients from the U.S., U.K., Africa, and beyond, Vin Hair doesn’t just sell hair, they guarantee quality from the first step of the process to the last package. Their inspection process plays a vital role in building long-term credibility with overseas buyers.

2. Step-by-step how Vin Hair inspects hair quality

Read these 8 steps below to explore Vin Hair’s hair quality inspection process:

2.1. Step 1: Hair collection & preliminary check

It begins with careful sourcing. Vin Hair collects hair from healthy Vietnamese donors, predominantly rural women who retain traditional hair care practices.

- Even before processing, the hair is examined early to see if it meets these basic criteria:

- Collected from Vietnamese donors

- No lice or nits

- No pre-dyed or chemically treated hair

- Only virgin and clean hair makes it to this first cut.

2.2. Step 2: Deep washing & sanitation

Once the hair passes initial quality checks, it is deeply washed and sanitized to remove dust, sweat, or natural oils.

Vin Hair utilizes:

- Herbal and sulfate-free shampoos for washing without killing the cuticles

- Sanitation methods according to hygiene standards without chemicals.

This process renders the hair clean, scented, and free of bacteria or residue before processing.

2.3. Step 3: Natural drying & texture preservation

To conserve the natural integrity of the hair, Vin Hair does not apply industrial dryers. Rather, hair is dried naturally indoors in controlled temperatures, which helps:

- Maintains natural shine

- Helps prevent frizz and dryness

- Retains natural wave or curl formation

This gradual drying process is critical to maintaining the hair’s softness, health, and durability.

2.4. Step 4: Sorting by length, texture & color

Following drying, the hair is hand-sorted by:

- Length: Measured from root to end in an outstretched position for accuracy

- Texture: Wavy, curly, kinky, or straight textures are categorized equally

- Color: Natural colors (black, dark brown, light brown) are matched to preserve consistency

This guarantees consistency in each bundle so wholesalers and salon owners can readily fill bulk orders with exact specifications.

2.5. Step 5: Tangle & shedding resistance test

Each bundle undergoes tangle and shedding resistance tests before packaging to ensure durability and a smooth user experience during styling.

Vin Hair staff perform:

- Brush tests to assess whether the hair tangles easily or maintains a silky texture

- Pull tests to check for excessive shedding under typical styling pressure

- Only bundles that pass these mechanical stress tests proceed to the packaging stage.

2.6. Step 6: Heat and dye resistance check

Vin Hair is aware that the majority of clients will curl, style, straighten, or color the extensions. For this reason, they perform:

- Flat iron tests at high temperatures (180–200°C) to try heat resistance

- Color tests using gentle developer or bleach to determine if the hair can lift or accept color evenly

This way, they ensure that the hair behaves as natural, untreated human hair-receiving it in an appropriate manner for salon treatments.

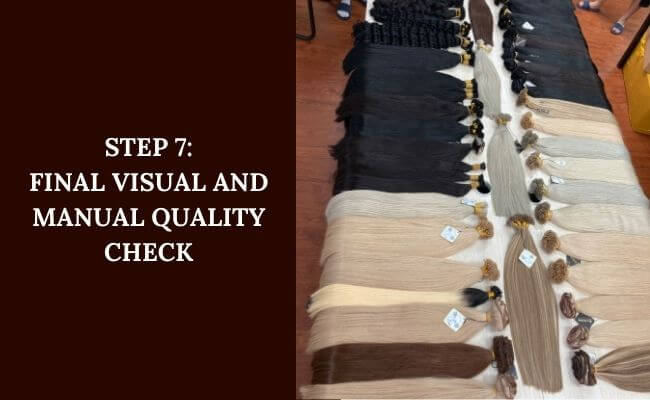

2.7. Step 7: Final visual and manual quality check

Senior staff members check all bundles once and for all before they exit the factory. This step is a comprehensive, final inspection of the product’s appearance and structural integrity before shipment.

At this stage, senior staff members perform a thorough review to ensure:

- Consistency in length and thickness across all bundles

- Shiny, smooth-cut cuticles that align in one direction

- Zero signs of tangling, matting, or visible damage

- No split ends or coarse strands

- Each approved bundle is labeled, logged, and verified against the customer’s exact specifications to ensure top-notch quality control.

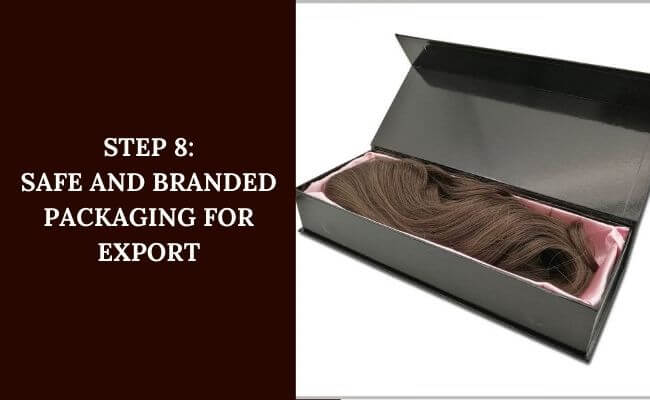

2.8. Step 8: Safe and branded packaging for export

Once the hair has passed all the quality checks, it’s ready for exportation. Vin Hair uses:

- Dust-free, waterproof packaging to keep the hair in its natural state

- Branded labels and stickers to identify the product and build customer trust

- Private labeling or bulk packaging options for private label customers or wholesale customers

- Packages are double-boxed and then handed over to reliable shipping companies for fast, traceable global shipping.

Conclusion

Vin Hair inspects hair quality process, which ensures every bundle of hair is export-grade, clean, and healthy. From ethical harvesting and gentle washing to durability testing and safe packaging, Vin Hair insists on quality every step of the way.